In ultrasonic spray coating, a polymer solution is atomized in a nozzle actuated by an ultrasonic generator. The resulting microdroplets can be deposited on the substrate by an air flow coupled in the ultrasonic nozzle. Spray coating is very versatile, allowing to cover both flat, curved and pre-patterned substrates with conformal polymer coatings. Furthermore, spray coating of other liquids such as biomolecules in solution is possible. We have applied spray coating for deposition of thin polymer films on drug delivery devices for pH-triggered release and micromechanical sensors to study biopolymer properties and degradation.

Spray coating of polymer films

A large number of parameters such as the substrate temperature, the distance between nozzle and substrate, the concentration and flow rate of the polymer solution or the nozzle speed have an influence on the texture, uniformity and thickness of spray coated polymer films. We have investigated spray coating of polymers such as PDLLA, PLLA, Eudragit® or chitosan.

Selective polymer deposition on 2D and 3D surfaces

Typically, photolithography is used for subsequent patterning of spray coated films which requires that the polymer is photosensitive. Direct spray coating of polymer patterns could remove considerable limitations on the composition of the processed material. In practice, direct writing of micropatterns by spray coating is impossible because the typical diameter of a spray coating beam is in the mm-range. We have investigated the use of shadow masks to restrict polymer deposition on 2D and 3D substrate to well-defined areas with dimensions between 150-400 µm. For this purpose, we developed novel methods for fabrication of ferromagnetic shadow masks (Ni) to allow for magnetic clamping to the substrate.

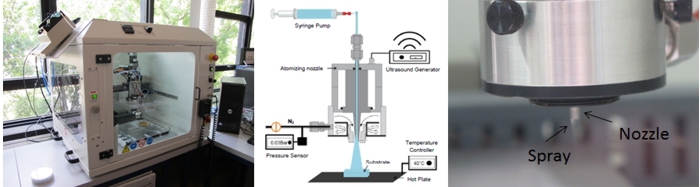

Equipment

The equipment for spray coating is an ExactaCoat system from SonoTek (USA), with control of X-Y-Z motion of the nozzle and a heating plate. At present, AccuMist and Impact nozzles with a frequency of 120 kHz are available. The polymer solution is introduced with a syringe pump operated from the spray coating software interface.

Publications

-

S. Bose, S.S. Keller, T.S. Alstrøm, A. Boisen, K. Almdal ”Process optimization of ultrasonic spray coating of polymer films”, Langmuir 29 (2013) 206911-6919

- S.S. Keller, F.G. Bosco, A. Boisen ”Ferromagnetic shadow mask for spray coating of polymer patterns”, Microelec. Eng. 110 (2013) 427-431

Collaborators

Prof. Kristoffer Almdal, Amphiphilic polymers in biological sensing group, DTU Nanotech

Prof. Anja Boisen, Nanoprobes group, DTU Nanotech

Last updated 14.12.2016, Stephan Sylvest Keller