PolyFabLab

About PolyFabLab

New lab, new opportunities

PolyFabLab is designed to close the gap between research laboratories and the cleanroom environment, enabling PDMS processes and polymer printing in a 140 m² ISO 7 cleanroom.

The facility offers an open floor plan with direct views from the new panorama café, creating a unique opportunity for guests and students to experience cleanroom operations up close.

PolyFabLab has been equipped with brand-new instruments funded by the Novo Nordisk Foundation, alongside selected equipment and processes from previous facilities.

We look forward to welcoming you to PolyFabLab in Building 347 and to exploring the new possibilities this facility brings to research and innovation.

Construction Process

Follow the building project as it proceeds

Building 347

The existing building 347 will house the new PolyFabLab and is being prepared for the construction.

Ground Floor

The ground floor is being prepared for the construction. Staff members have moved to other buildings (345, 358, 451).

Ground Floor

The previous PackLab is ready to be transformed into the new PolyFabLab.

ground floor

The wall between the old kitchen and lunchroom has been demolished to make room for a huge pane of glass separating the new "Panorama Cafe" from the coming lab.

first floor

A new kitchen and lunchroom is slowly taking shape on the first floor. A part of the wall is now gone to open up the space between the kitchen and lunchroom.

first floor

The old PackLab on first floor is being demolished to make room for two new large offices.

first floor

New ceiling and paintwork in the new kitchen area

first floor

New ceiling and paintwork in the new lunch-room

Ground Floor

Supplies for the cleanroom are coming from the basement, including makeup air ducts and gas lines.

Ground floor

Floordrain for the emergency shower.

Ground floor

Left: Floor preparation for the Panorama Café. Right: Temporary gowning area in the hallway to minimize dust during the installation of the cleanroom.

ground floor

Temporary gowning in Flemming's previous office :)

ground floor

Yellow film (LithoProtect) on the window frames. Epoxy coating on the walls and ceiling to maintain a smooth and particle-free environment.

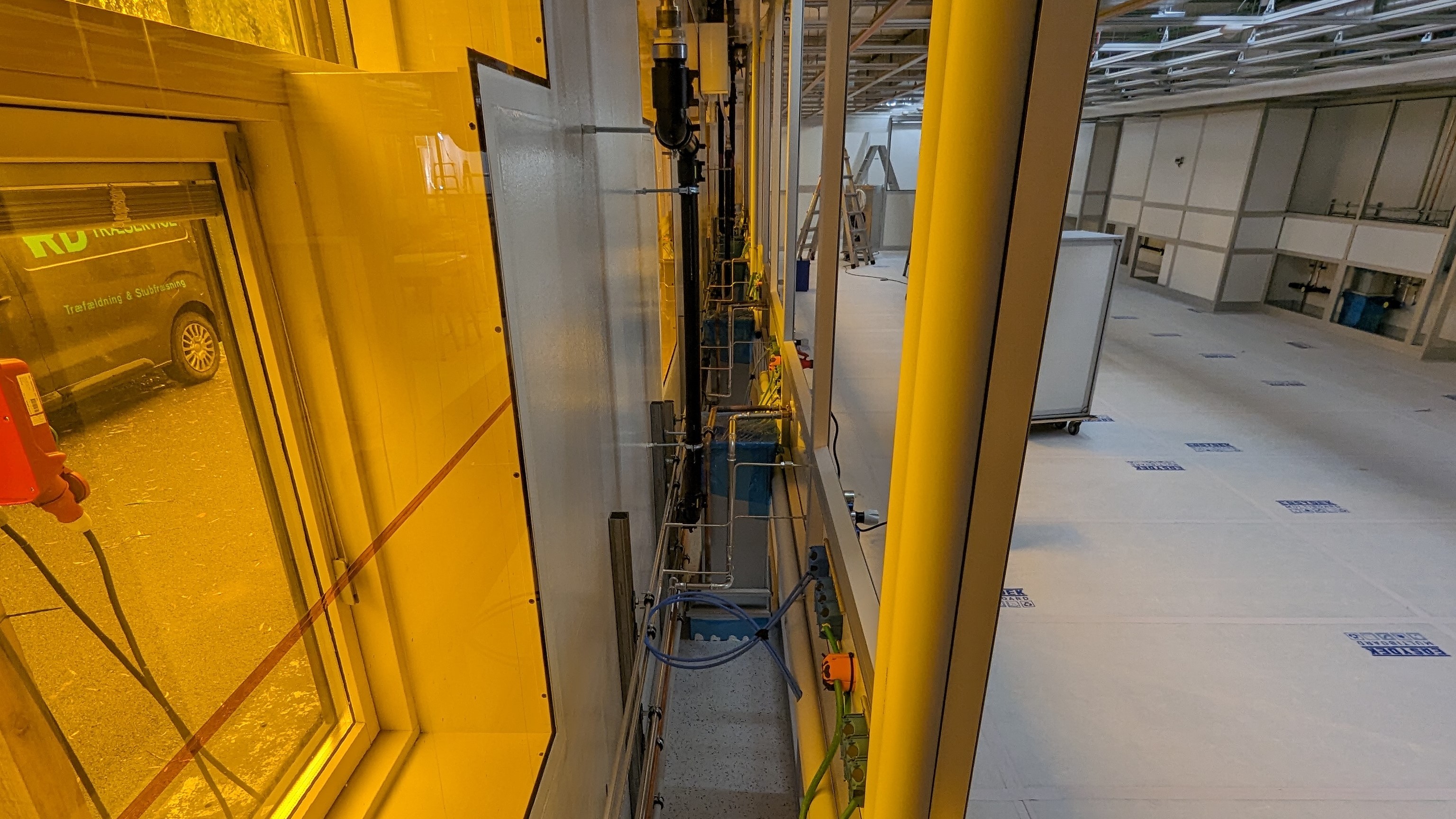

ground floor

Perimeter wall for circulating air and lab supplies.

ground floor

The panorama window between the panorama cafe and the cleanroom.

Ground floor

Exhaust duct.

Ground Floor

The cleanroom in November 2023.

Construction of the basement

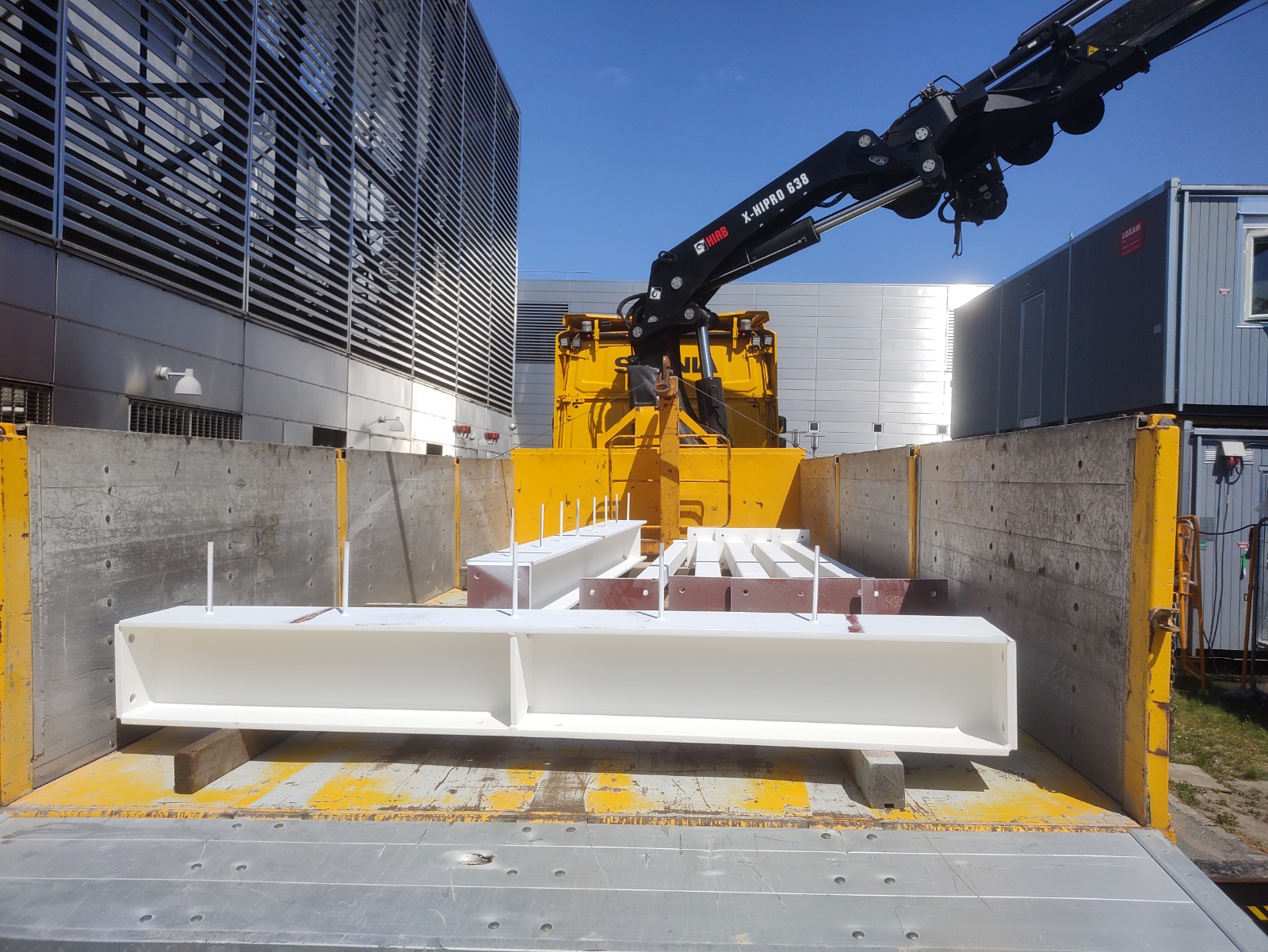

Basement

These foundations will ensure a future capacity for machines weighing up to 500Kg/m2. The old floor was designed for a maximum load of 250Kg/m2.

Basement

New foundations are being cast in concrete to support the pilars mounted under the floor of the new lab above.

Basement

The basement floor before the pouring.

basement

Delivery of steel pillars.

basement

Heavy steel pillars are being raised on the concrete floor in the basement to support additional load from equipment in the PolyFabLab above.

basement

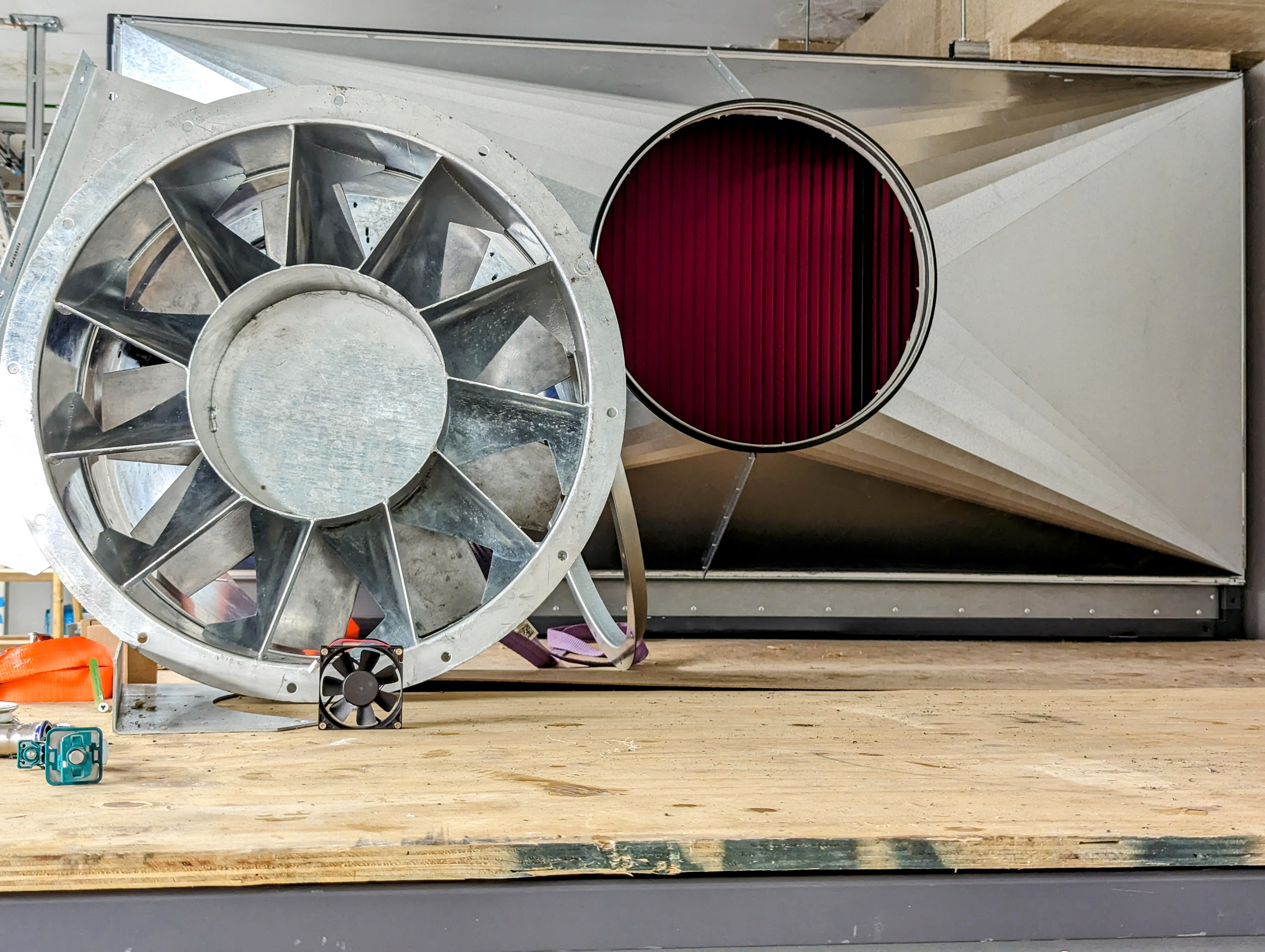

Basement

The exhaust fans and the ventilation duct is about to be installed.

Basement

basement

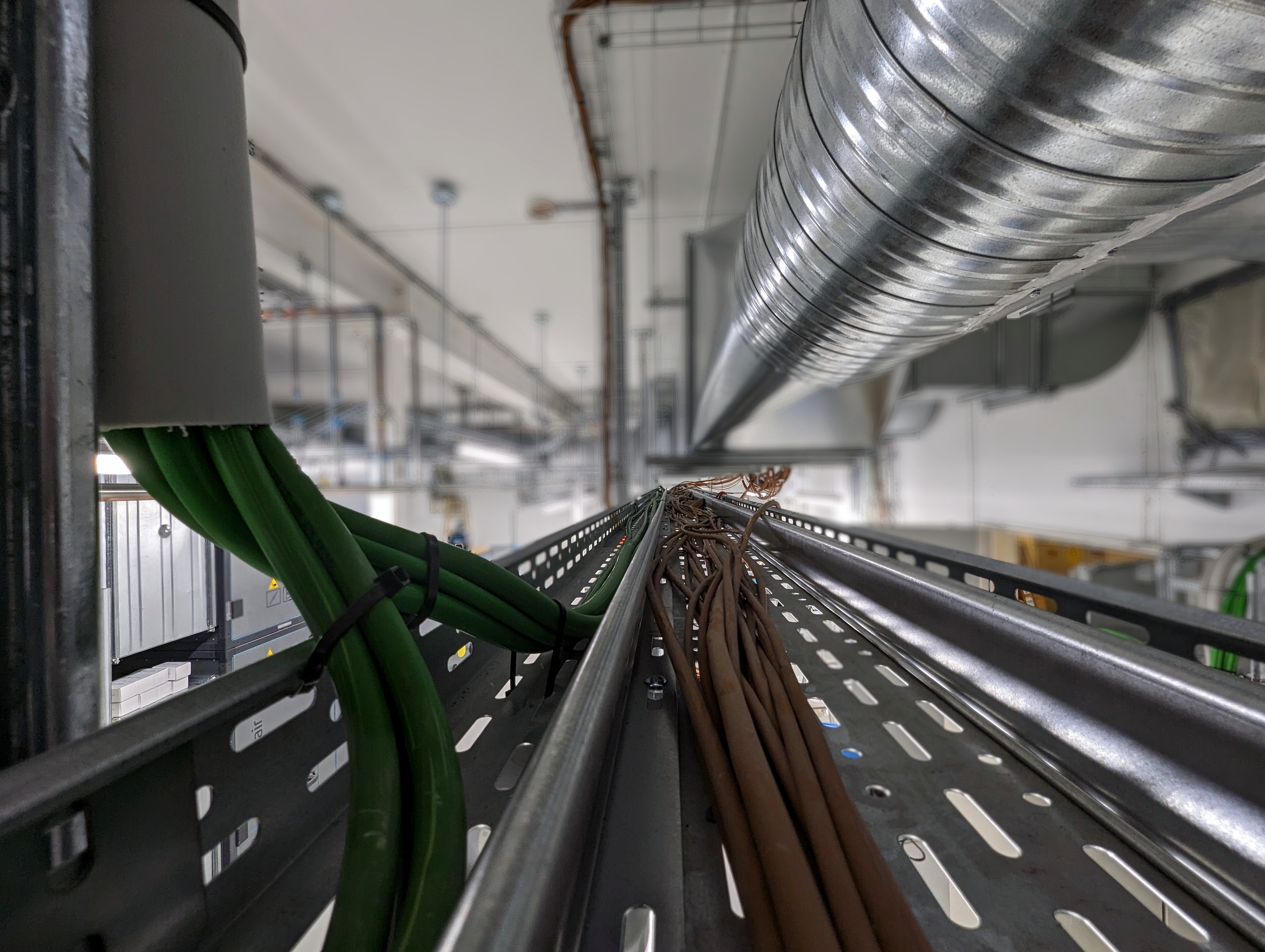

The gas pipes have been mounted.

basement

The elictricians have prepared the leads.

basement

The cooling water system is being installed.

Contact

For further information, please contact the following staff members

Contact

Meena Dhankhar PolyFabLab manager

Contact

Leif Steen Johansen Head of Operations, Ph.D.

Contact

Anders Skjoldager-Gregersen Research Laboratory Manager

Contact

Stephan Sylvest Keller Professor

Project Group (PG) and Scientific Steering Committee (SSC)

Member of PG

Anders Skjoldager-Gregersen Research Laboratory Manager

Member of PG

Conny Hjort Laboratory technician

Contact

Stephan Sylvest Keller Professor

Member of PG and SSC

Rafael Taboryski Professor

Member of PG and SSC

Ada-Ioana Bunea Associate Professor