DTU Nanolab offers automated process, low-contamination samples and wider range applications

The new microscope is a combined scanning electron microscope (SEM) and focused ion beam (FIB) microscope with 4 different ion species. It will be primary dedicated to sample preparation for TEM but it also offers improved imaging resolution with the electron beam.

Conventional FIB microscopes use Ga+ ion beams to cut through material and micro/nano machine structures. One side effect of the process is implantation of Ga into the structures, sometimes referred to as ‘Ga-poisoning’. To mitigate this previously, we had to transfer samples into Ar+ ion milling machines and further process them. This is no longer a problem in Helios Hydra which uses Xe+ and Ar+ to do the entire milling process. It also offers the possibility of switching to O+ and N+ beams, which are useful for cutting other range of materials such as polymers or chemical treatment of surfaces.

Another major advantage of Helios Hydra is its advanced level of atomization. FIB specimen preparation is time consuming and entails many delicate steps. It often takes new users many practice sessions to master the process. The sophisticated software in the new Helios Hydra FIB however takes care of most of these steps with few initial input needed from the user. This will simplify both the training of new users and improve the time-efficiency of microscope usage.

By the summer of 2021, the Helios Hydra Plasma FIB will be available at DTU Nanolab.

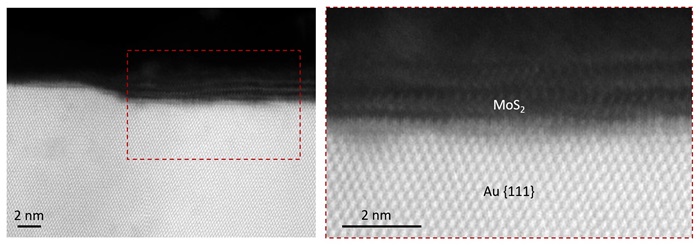

Atomic-resolution STEM images of 2 layers of MoS2 on the surface of a Au {111} substrate. The thin film specimen was prepared by Helios Hydra for TEM examination (sample grown by the Nanomade group at DTU Fysik).